Analytical Testing & Quality Control

Our team of experts can test and evaluate the stability of a vast range of therapeutic modalities, using a wide panel of analytical techniques to support the specification and shelf life setting, and ensure regulatory compliance.

Quality Control Services in our locations

BASE® in Basel

Swissmedic approved GMP testing facility:

- clinical and commercial drug substance (DS), drug product (DP) for release and stability testing

- analytical method handover (e.g. from development)

- analytical method validation/verification

- analytical method transfer

- local stability storage infrastructure

≤-60°C; -20°C; 5°C implemented

25°C/60%rH; 30°C/ 65%rH; 40°C/75%rH

ISO9001:2015 certified method development labs

VIVA2® in Visp

Swissmedic approved testing facility:

- Bioburden

- Sterility

- Endotoxin

- Monitoring samples (clean rooms and clean utilities - full analytics)

- Identification of microorganisms

- Microbial challenge studies

- IPC protein concentration

- Excipients testing

Compliance with EP/USP/JP requirements

Analytical Testing and Quality Control services in detail

Method development, validation, and transfers

Our team of experts can develop and validate appropriate analytical methods, to assess content, purity, identity, and compliance with pharmacopeial requirements and methods. This includes physico-chemical testing and microbiological testing.

Our team can also implement and transfer analytical methods from any 3rd party.

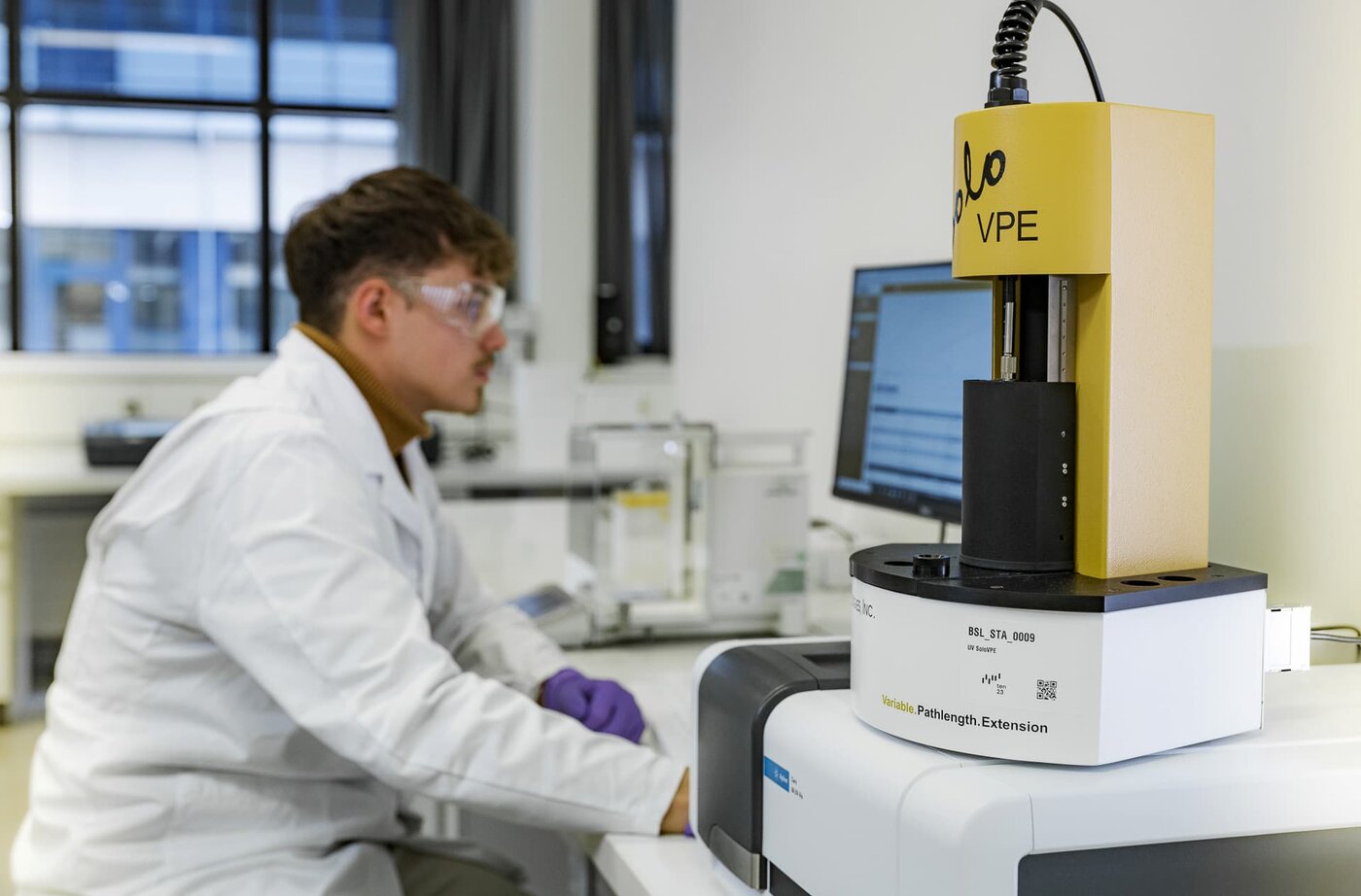

Our analytical services panel includes a vast range of methods and equipment, allowing us to perform pharmaceutical testing on various therapeutic modalities, from small molecules to biologics and others, ensuring adherence to rigorous quality and biosafety level standards.

QC (Quality Control), Release & Stability Testing

We perform release and stability services, either in combination with Development or Drug Product Manufacturing, or as a stand-alone service. We can perform QC release testing according to cGMP for clinical and commercial Drug Products, including physico-chemical and microbiological testing, including identity, content, purity, and pharmacopeial and microbiological endpoints.

Stability testing is required to determine an appropriate shelf life and evaluate product stability. Our qualified walk-in stability chambers include refrigerated (2-8°C), 25°C/60% r.h, 30°C/65% r.h., 40°C/75% r.h. and we can also evaluate stability in a frozen state (-20°C, -40°C, <70°C). Additionally, we can perform Photostability testing (according to ICH).

For development purposes we would also typically recommend evaluating interfacial stresses.

Characterization and Comparability

We at ten23 health can also support you in characterizing pharmaceutical products of therapeutic modalities, for example comparing any changes and product versions, may it be due to different processing, before/after site transfers, or any formulation, packaging, or device changes, etc. Such comparability assessments can also help compare molecules to their physiological counterparts or any other relevant reference products.

Special Analytics

We also provide special analytical services as follows:

- Particle Characterization: Utilizing a range of advanced instruments and technologies—such as nanoparticle tracking analysis, light obscuration, and flow imaging—we can measure and count particles within the submicron to subvisible size range. We can provide insight into particle morphology, enabling effective classification and differentiation.

- Particle Identification: Identification is performed through digital microscopy and FTIR spectroscopy, supported by complementary analytical methods for enhanced accuracy and details.

- Pharmacopeial Testing: Key pharmacopeial analyses can be conducted in compliance with ISO standards and cGMP requirements.

- Container Closure Integrity (CCI) Testing: we can assess container closure integrity and typically recommend deterministic CCI testing using Helium leakage. We can perform these evaluations with various container options including polymer containers. We can also support other CCI assessments.

- Device functionality testing: our assessments can include functionality testing for syringes, cartridges, or other functional containers. This would include break-loose and glide-force testing (BLGF).